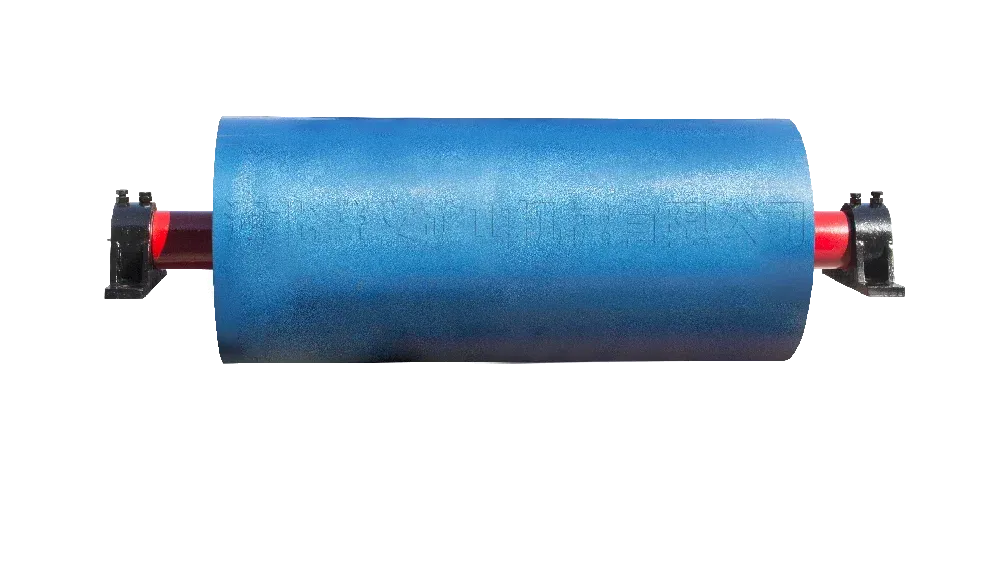

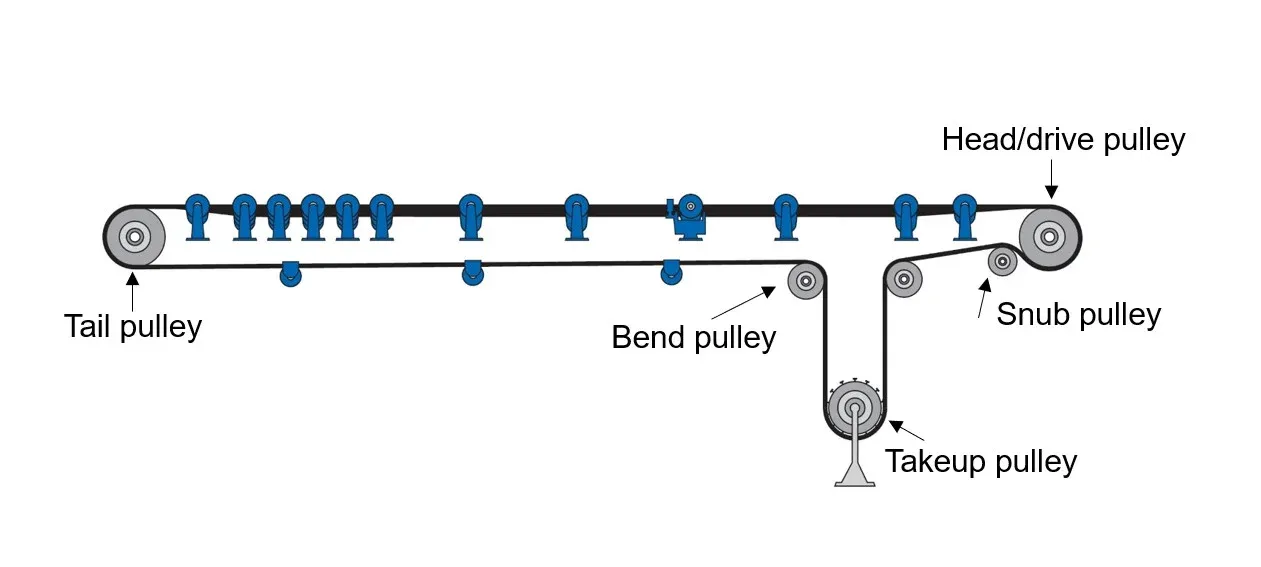

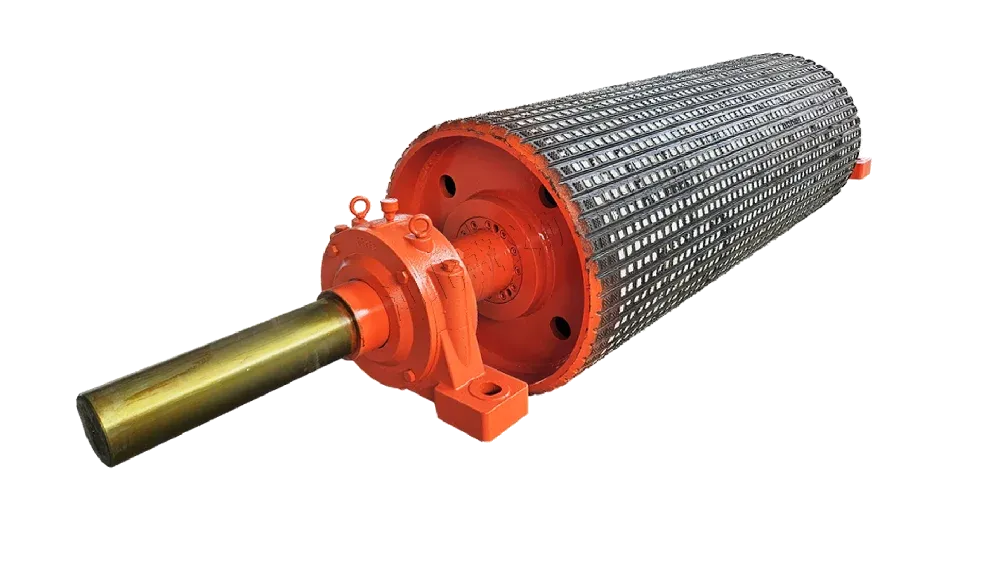

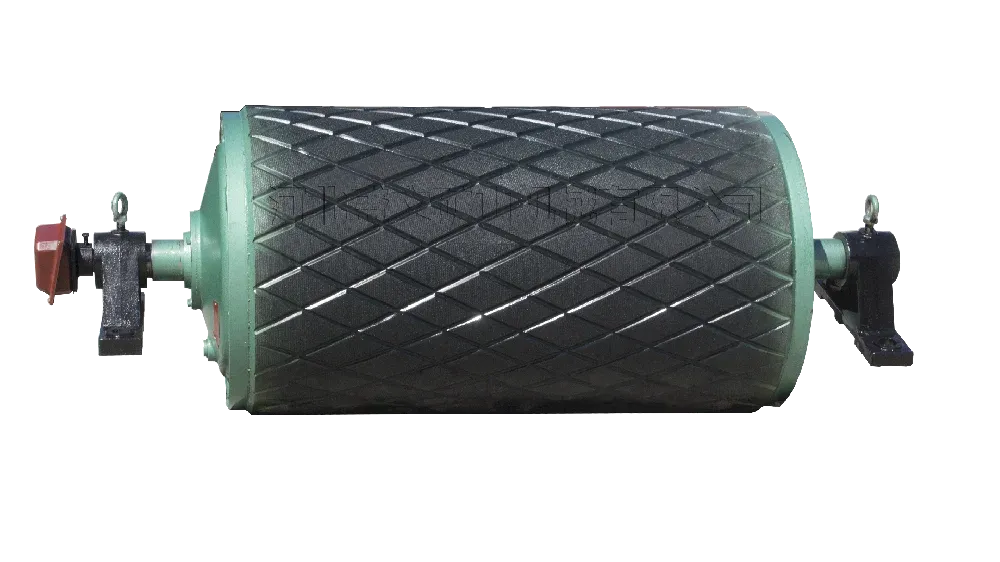

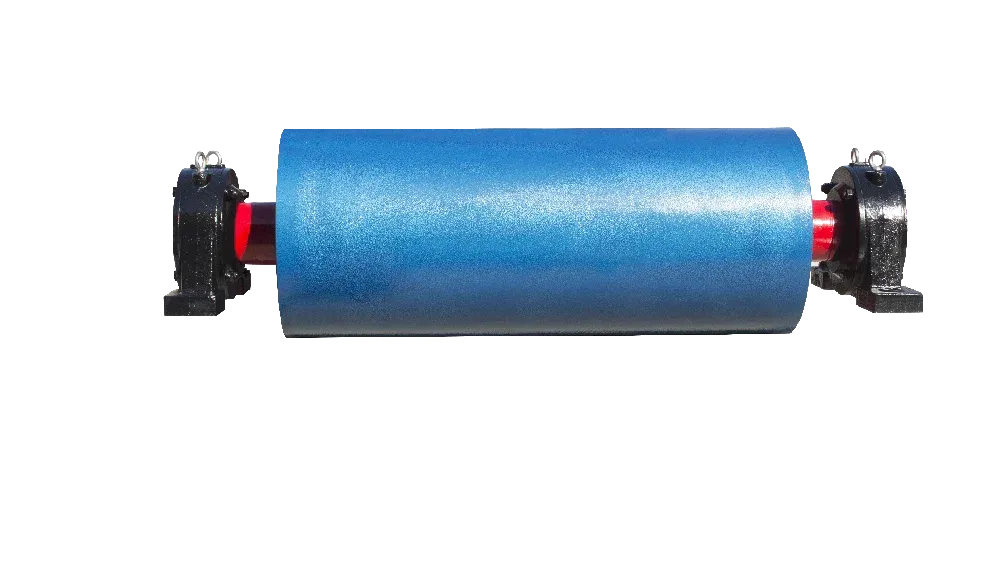

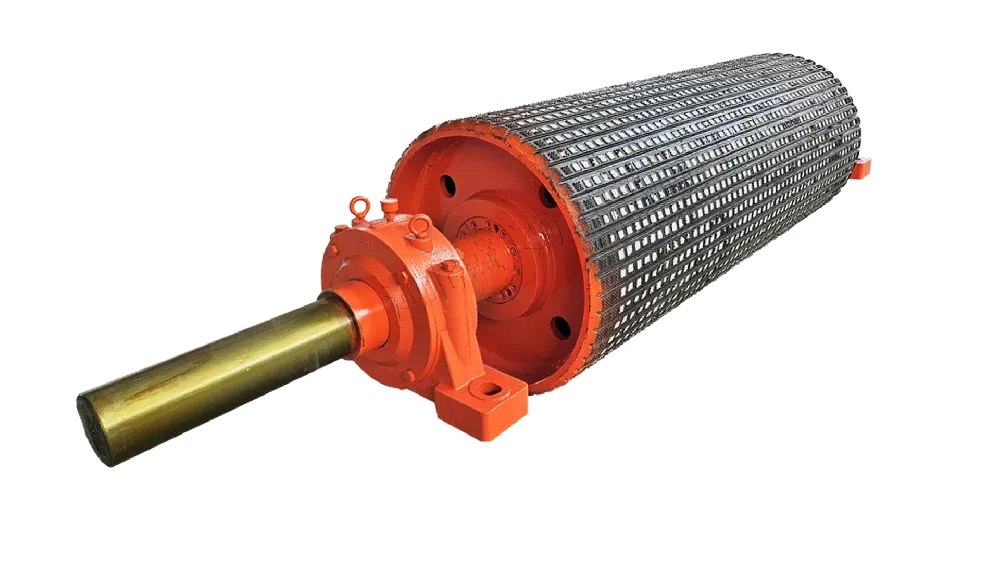

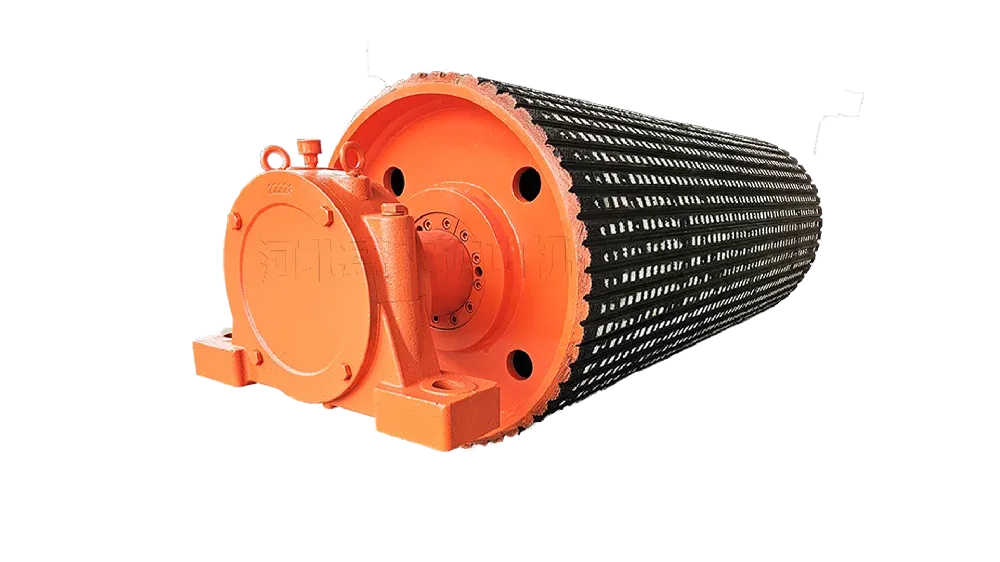

I. Preparation before Work Shift (1) Accept the task. (2) Identify and assess potential hazards, implement the project's safety and technical measures, and sign for confirmation. (3) Wear qualified labor protection supplies and work with a valid certificate. (4) Approval form for safety and technical measures. II. Verify Spare Parts Check the specification, model, and technical parameters of the drum of the belt conveyor. III. Prepare Tools, Equipment and Materials (1) Prepare tools such as wrenches and sledgehammers, as well as lifting equipment and materials, and transport them to the work site. The tools and lifting equipment should be complete, suitable, and in good condition, and the materials should be complete. (2) Work forms, material requisition form (washing and sorting). Safety Tip: The lifting equipment should be within the mandatory inspection period and comply with the standards. IV. Apply for Power Outage (1) Designate a specific person to apply to the centralized control room for the power outage procedures of relevant equipment and clearly define the maintenance content. (2) After the centralized control room confirms the power outage, it notifies the power outage applicant to test for electricity. (3) Work forms, power outage and restoration work ticket (washing and sorting). V. Test for Electricity Test for electricity on the powered-off equipment and confirm the power outage. After contacting the operator at the post for confirmation, perform a jog test for electricity. Safety Tip: In a special environment, if the concentration of gas and coal dust is not detected, accidents are likely to occur. VI. Lockout Lock the control switch of the powered-off equipment and put on a lock. The lockout should be in place and the lock should be reliable. The key should be kept by the person who locks it. VII. Fix the Belt Use special belt clamps to grip the lower belt, and tighten and position it. The lower belt should be firmly fixed without any movement. Safety Tip: In the explosion-proof area, check the concentration of gas and coal dust. VIII. Loosen the Tensioning Device (1) Hang the tensioning counterweight. (2) Lift the counterweight. (3) Install the protection chain. IX. Separate the Cleaner and Loosen the Belt at the Head Use special belt clamps to grip the upper belt, separate the cleaner, and move the belt upwards towards the head of the conveyor. Separate the belt from the drum to create a maintenance space. X. Fix the Belt Use special belt clamps to grip the upper belt, and tighten and position it. XI. Remove the Protective Cover Remove the protective cover of the pulley and place it in the designated position. XII. Remove the Connecting Components of the Coupling (1) Remove the fixing bolts of the elastic pins and place them in the designated position. (2) Remove the elastic pins and place them in the designated position. XIII. Remove the Drive Drum (1) Hang the drum and the belt. (2) Remove the foundation bolts of the drum. (3) Lift and transport the drum to the designated position. XIV. Remove the Coupling (1) Mark the installation position of the drum coupling. (2) Remove the drum coupling and place it in the designated position. XV. Clean and Inspect (1) Clean the mating surface of the drum. (2) Clean, inspect the assembly parts of the new drum and the coupling, and measure the assembly dimensions. XVI. Install the Coupling XVII. Install the New Drive Drum (1) Lift and transport the new drum to the installation position. (2) Level and align the coupling. (3) Tighten the foundation bolts. XVIII. Install the Connecting Components of the Coupling Install the elastic pins and tighten the bolts. XIX. Install the Protective Cover XX. Remove the Clamps Remove the clamps for fixing the belt. The belt should not be damaged. XXI. Adjust the Tensioning Device (1) Remove the protection chain. Lower both sides simultaneously. (2) Lower the counterweight. Adjust the counterweight to meet the operation requirements. (3) Reset the cleaner. The cleaner should have good contact with the belt. XXII. Clean the Work Site (1) Take an inventory of tools, equipment, materials and accessories. (2) Clean up the sundries at the work site. XXIII. Apply for Power Restoration (1) The person who applied for the power outage applies to the centralized control room for the power restoration procedures. (2) The electrician restores the power, and the person who locked the equipment removes the lockout. (3) Work form: Power outage and restoration work ticket (washing and sorting) XXIV. Test Run and Follow-up (1) Notify the operator at the post to conduct a test run. The drum should run smoothly without abnormal noise, and the temperature rise of the bearing should not exceed 35 degrees Celsius. (2) Conduct operation follow-up and record. XXV. Fill in the Records Record the maintenance content. Work form, equipment maintenance record (washing and sorting).